SLUDGE/SEDIMENT REMOVAL – STORAGE TANKS & PITS

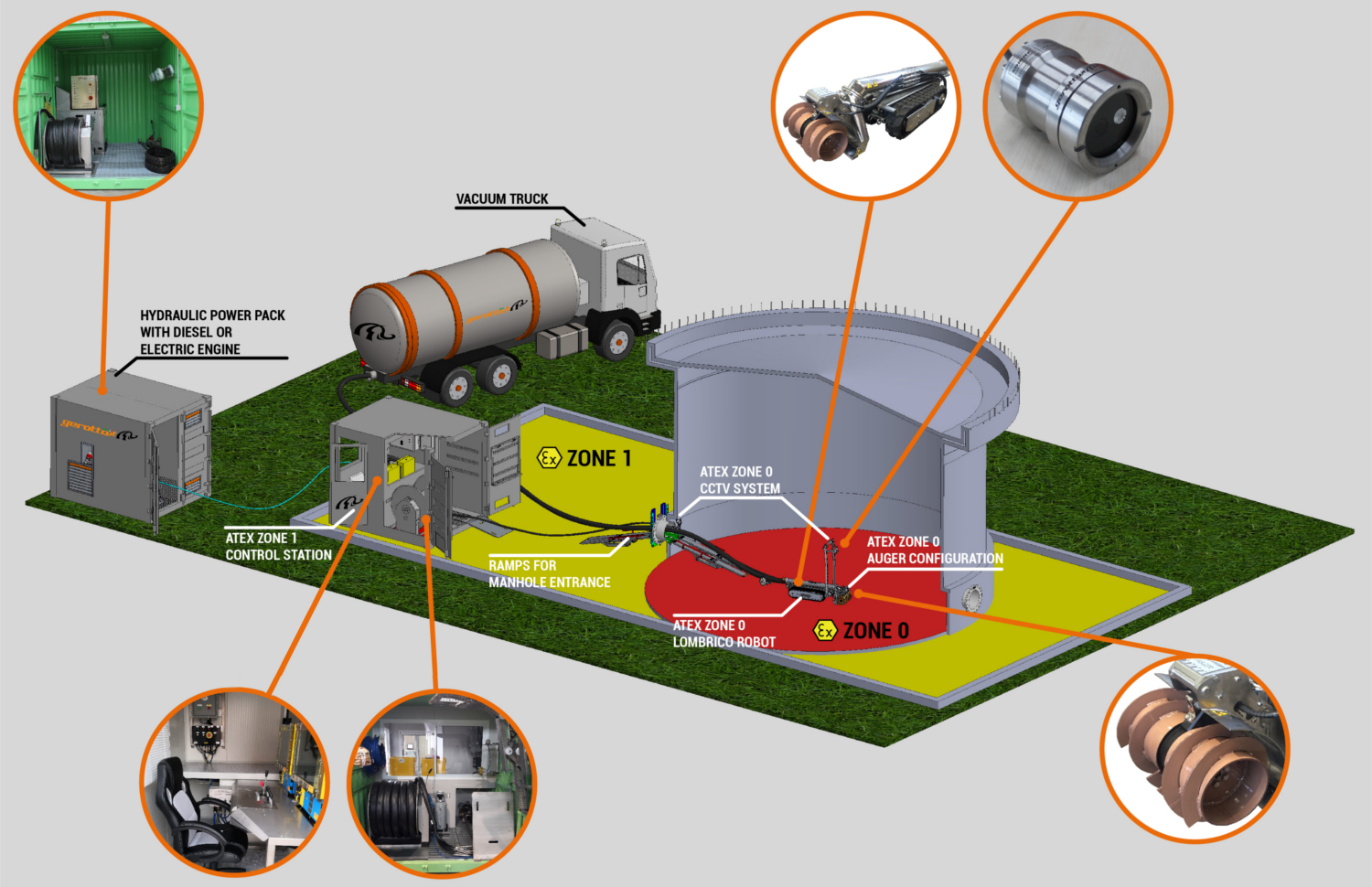

Sludge and sediment removal is an essential task that oil storage facilities, refineries, and processing plants must make part of their facilities maintenance procedures. Oil storage tanks and pits can accumulate sludge and sediment in different ways. Oil in tanks, when exposed to moisture — say, from the air — can oxidize and form sludge. Sludge can also form whenever crude and its derivatives are left in storage, undisturbed, for long stretches. During this time, heavier products can settle as sediment and sludge at the bottom of the tank. Raw or natural petroleum could be contaminated with sand, shells, aggregates, vegetation, and even water upon extraction. Pits may also be subject to sand and water incursion. These contaminants can build up over time, turning into problem sludge and sediment. Sludge and sediment inside oil storage tanks lead to oil quality inconsistencies. Sludge and sediment also occupy valuable tank space and might lead to the corrosion of the tank’s bottom and inner walls. They cause uneven weight distribution, which could lead to undue stress on the tank structure. Accumulated sludge and sediment can damage floating roofs and prevent them from creating a tight seal. AWE has a range of sediment and sludge removal pump solutions. Our remotely operated sludge removal equipment is ideal for industrial sludge removal applications, such as crude oil sludge removal from storage tanks. Oil storage tanks contain toxic fumes, so it is not safe for your crew to get in there to clean them manually. Our robotic no-man-entry sediment removal solution and sludge removal system safeguards the health and safety of your crew.

Why customers come to us:

- Custom-built sediment and sludge removal systems to suit specific requirements

- ATEX Zone 0 rated equipment available

- No-man-entry options available

- Expert advice available on applications

Need an oil tank sludge remover? Talk to us today!