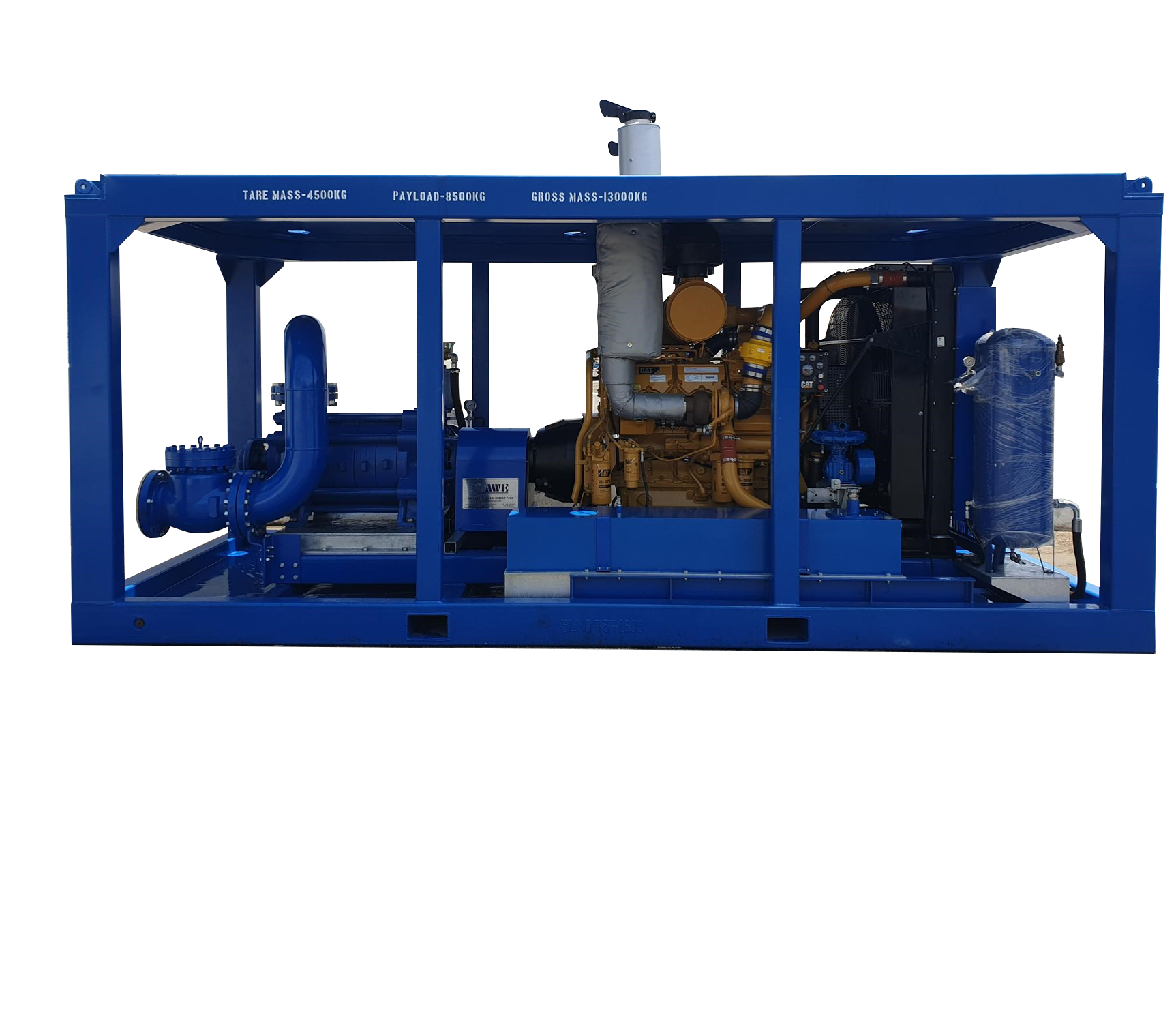

Multistage Pumps

Multistage centrifugal are so called because they contain multiple chambers and impellers (or stages) that are used to build pressure within the pump. The fluid will enter the suction flange of the pump and as it passes through the stages of the pump it will increase in pressure until eventually it will be discharged at the required elevated pressure. To increase the discharge pressure, additional stages are built into the pump while maintaining the desired flow. The pumps can be assembled with electric or diesel driven engines as required and also available in a range of material to suit the pumped medium.

1

4

Features

- In built self-priming arrangement

- 50CFM air removal capacity

- Wide range of material options for pumping different mediums

- Vacuum pump included for priming of the main pump

Benefits

- Can be assembled with electric or diesel driven engines

- Vacuum pump is driven by the auxiliary drive of the engine so no additional source is required

- Capable of suction lift up to 6m

Contact Us

Contact →