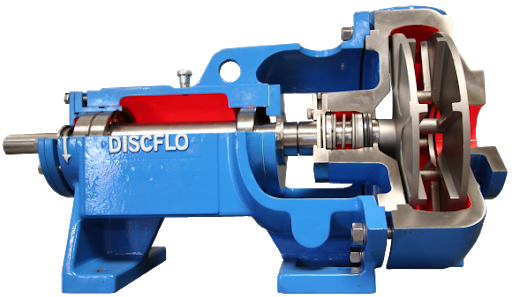

Disc Pumps

Without an impeller, piston, diaphragm or screw, the unique pumping mechanism of the disc pump is based on the effect of a boundary layer and viscous drag principle, which produces a pulsation-free laminar flow. This technology creates a low-to-no maintenance system by minimizing contact between the pump and the raw material being pumped. Wear on the disc pump components is greatly reduced resulting in pump longevity, reducing operational costs and saving hundreds of thousands of dollars in parts, maintenance and product loss. The powerful combination of superior abrasion resistance, gas-entrained pumping ability, non-cavitating and non-emulsifying and non-shearing laminar flow make the disc pump the ideal choice for the toughest applications. AWE proudly represents Discflo for all Disc Pump applications in the Middle East and Asia and is encouraged by the installations from the largest National Oil Companies in the region.

Features

- Non pulsating, laminar flow

- No radial loads

- No close tolerances

Benefits

- The layers of fluid at the walls are stationary (relative to the rotating discs), creating an protective boundary layer. Viscous drag pulls layers into flows of smooth laminar streams

- With no impingement device to damage your product and a boundary layer of protection for the pump, the disc pump effectively eliminates the root cause of clogging, cavitation, excessive wear and product damage that plague the performance of conventional pumps