Tube Cleaning

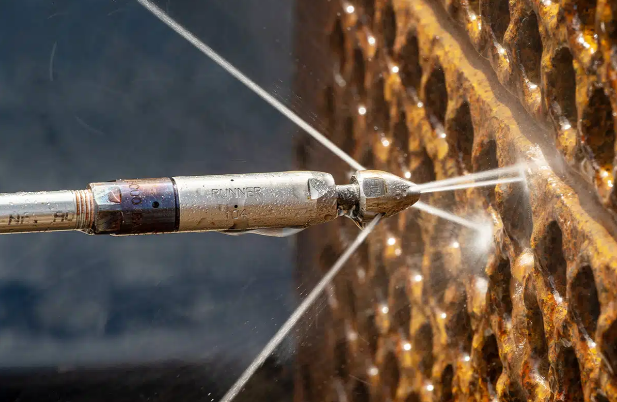

Industrial water jetting has many applications. Tube cleaning is one of them. Heat exchanger tubes, condenser tubes, evaporator tubes, boiler tubes, and fin fan tubes need to be maintained and regularly cleaned for operational efficiency. Interior-side and exterior-side, tubes can get fouled when a fluid’s chemical characteristics change, causing hardened salt deposits in or on the tubes. Fluids may also contain biological contaminants like algae as well as particles and sediment that can be deposited in and on the tubes. Likewise, a layer of corrosion products may gradually build up in and on the tubes. In time, all of these things can cause tube corrosion and blockages, which in turn lead to reduced operational efficiency and downtimes as tubes are repaired or a replacement is found. Ultimately, fouled tubes mean less effective cooling and, consequently, the processes that rely on their correct operation could suffer. Tube cleaning is, therefore, crucial to maintaining plants and facilities in many industries. AWE provides industrial water jetting systems suitable for all tube sizes and all types of tube assemblies. We have automated tube cleaning equipment including automated lancing machines with flexible and rigid options and a variety of nozzles and accessories for versatility, efficient cleaning, and the safety of human operators. We can also custom-build a high pressure water jet cleaning machine for certain applications.

Why customers come to us:

- Automation improves safety by removing operators using handheld equipment

- Less downtime when cleaning multiple tubes simultaneously using our single, twin, and triple lance solutions

- Consistent clean with adjustable lance feed rates

- Flexible lance and rigid lance solutions for cleaning in-situ or in dedicated cleaning bays

Contact us to inquire about our industrial water jetting systems for tube cleaning applications.