Process Pumps

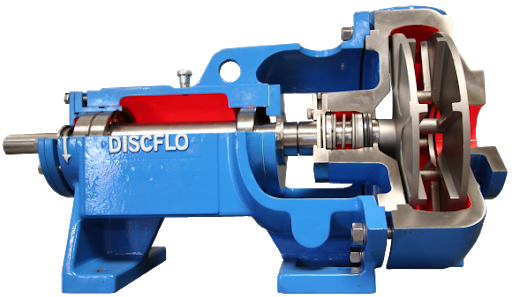

Process pumps refer to a category of pumps designed to move primarily viscous fluids and fluids with suspended solids. They have applications in oil and gas, paper and pulp, municipal water, chemical processing, general industry, and other industries. There are different types of process pumps. Conventional process pumps are mainly positive displacement pumps and centrifugal process pumps. However, disc process pumps like the Discflo Pump are a better option. Unlike conventional displacement and centrifugal pumps, disc process pumps utilize the boundary layer of fluid molecules as a natural buffer to separate the fluid from the pump. Meanwhile, viscous drag ensures fluid flows smoothly and with minimal impingement. Together, these things ensure there’s minimal contact between the pump and the material it is moving. This minimizes pump wear and tear, increasing service intervals and lowering maintenance costs. It also minimizes damage to the material being transported. AWE has a variety of disc pumps to suit various applications. API pump types satisfy the American Petroleum Institute or API pump standards, a requirement for process pumps in the oil and gas industry. Aside from API process pumps for high-temperature, high-pressure applications, there are also non API process pumps for operations that require a routine chemical process pump. The difference between API and non API pumps lies mainly in the type of material they can handle, with API pumps able to process highly aggressive and corrosive materials. AWE pumps also come in different configurations for flow rates that can go as low as 2 gallons per minute or as high as 10,000 GPM.

Why customers come to us:

- Variety of process pump types and configurations

- Lowest maintenance costs in the industry

- Amazing performance in difficult pump applications

- Handles solids, entrained air, and viscous products with ease

- Robust track record with NOCs and IOCs

Contact us to learn more about our process pumps.